Fiberline Building Profiles A/S

HD planks, A heavy-duty plank, typically used as decks for bridges with higher loads, such as cycle and footbridges. Handrails

The corrosive effects of effluent seriously damaged the aluminium bridge deck at the wastewater treatment plant in Aars, Denmark. The plant management decided to install a new deck built of GRP planks supplied by Fiberline.

Plant manager Poul Vejen: “The key consideration was safety. The aluminium could not withstand long-term exposure to effluent. The edges of the existing planks were eaten away and holes appeared. The bridge eventually became unsafe to walk on, particularly when carrying heavy loads."

But rotting caused by corrosion was not the only problem. When the aluminium panels expanded, they also moved and buckled, precisely where they needed to be strongest.

”The bridge had become unpleasant and unsafe to walk on and was also unsightly to look at. We therefore opted for a solution where corrosion would not be a problem,” continues Poul Vejen.

The plant management had previous experience of GRP in the form of guard rails supplied by Fiberline 10 years before in 1996. They therefore knew that GRP was not sensitive to corrosive environments and also what it was like to work with.

“We installed the new deck ourselves after some basic instruction. We also adjusted the Fiberline planks at the motor and drive gear. GRP composite is easy to work with,” says Poul Vejen.

As a further plus, the GRP deck was installed using the clips from the aluminium deck.

Fiberline is one of Europe’s leading GRP product manufacturers. According to the company’s Sales Manager Stig Krogh Pedersen, increasing interest is being shown by wastewater treatment plants in the use of Fiberline planks for walkways and tank covers.

“Fiberline planks have a number of advantages that are making them increasingly popular with treatment plant managers. They are long-lasting and require virtually no maintenance. At the same time they are easy to install, thereby saving both time and money,” adds Fiberline’s Sales Manager Stig Krogh Pedersen.

In addition, they produce tight joints and expansion is negligible.

“A further requirement from customers is a non-slip surface, and the quartz sand surface of our Fiberline planks gives plant personnel a secure foothold in wet and greasy conditions.”

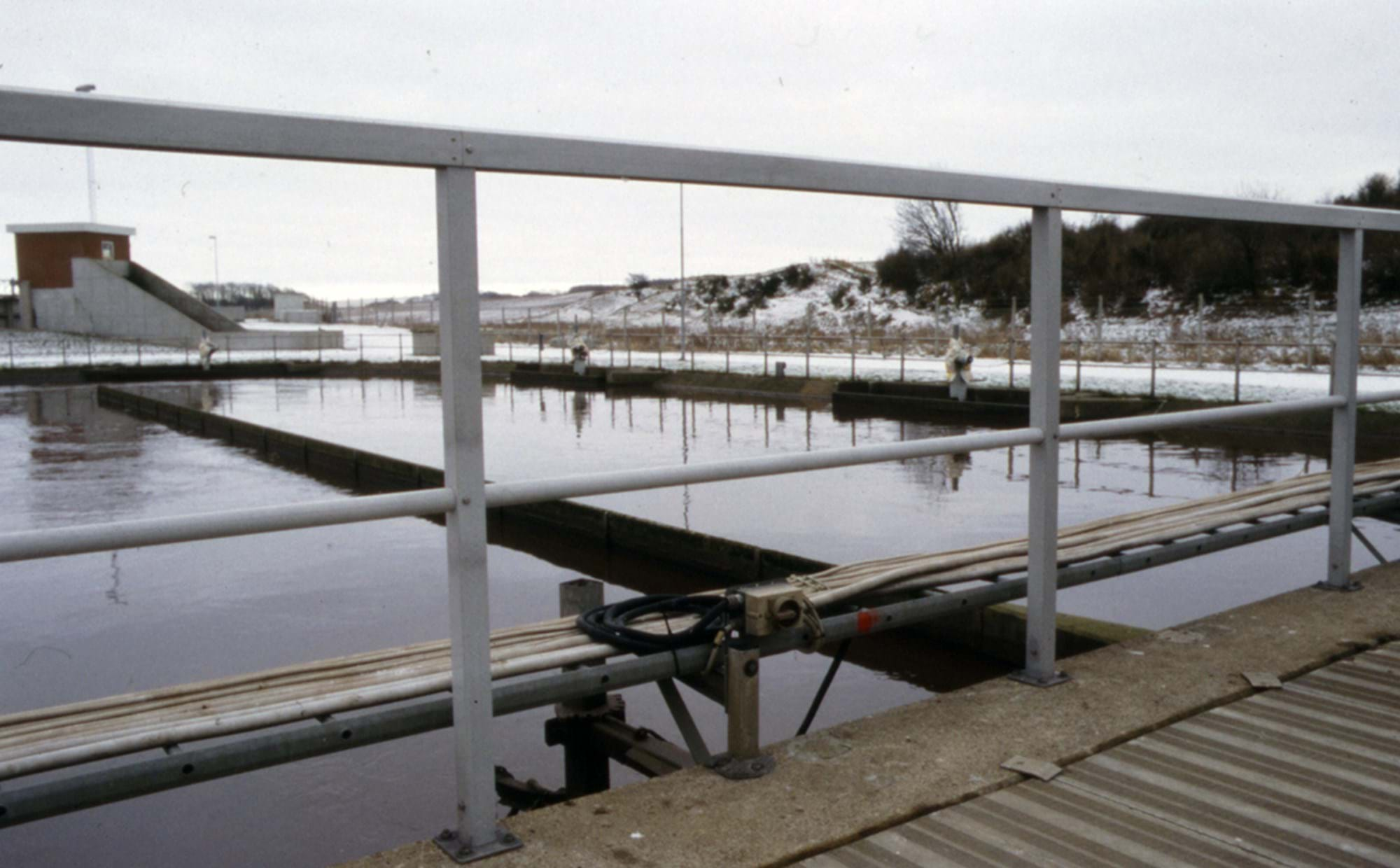

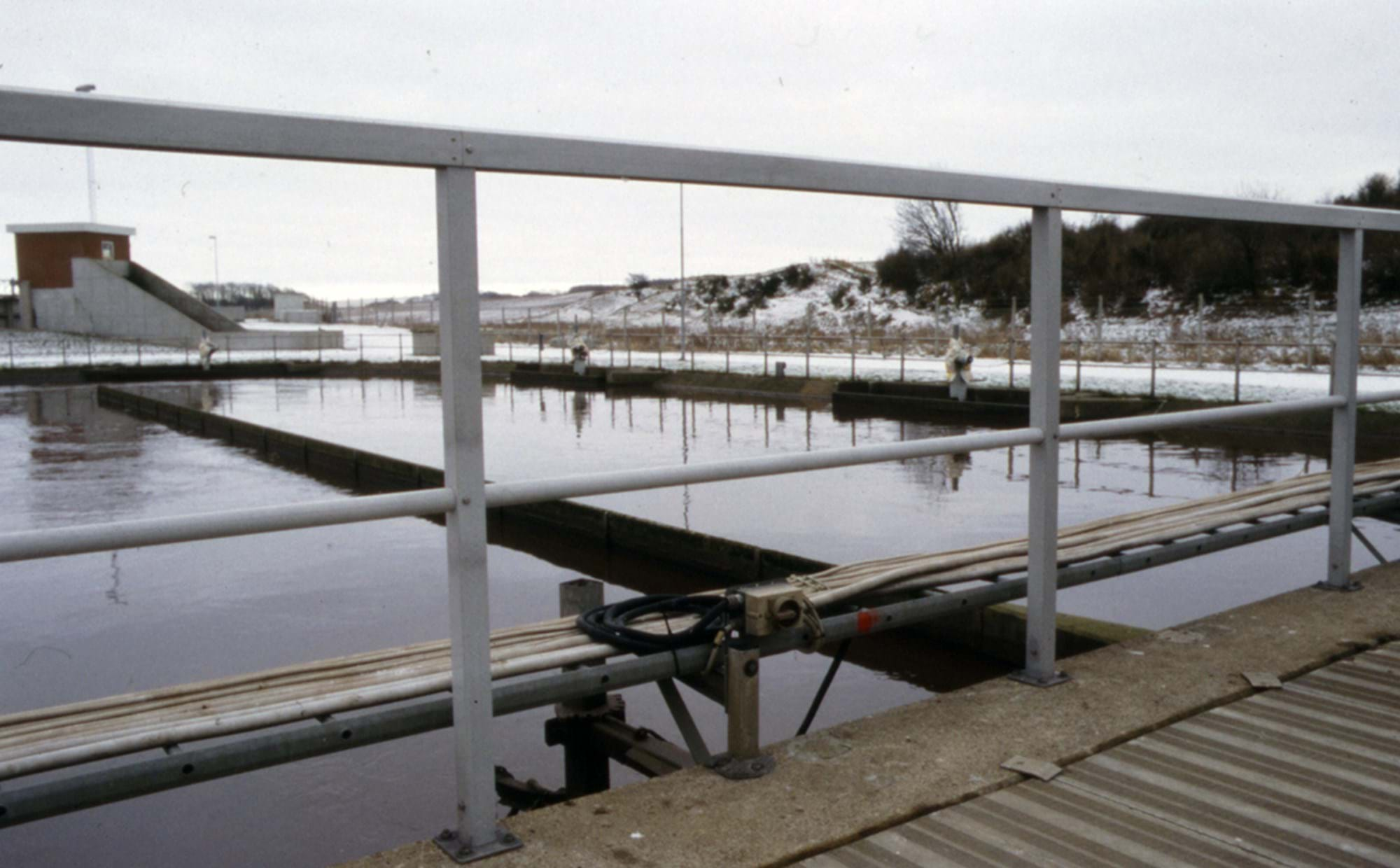

Showing the guard rails shortly after installation in 1996. Ten years later their condition testifies to the durability of GRP composite. The change in the aluminium planks between 1996 and 2006 is also clearly evident.

The corroded and buckled plates made walking on the bridge both unpleasant and unsafe, particularly when carrying heavy loads. The deck had also become an eyesore. Equipped with GRP planks from Fiberline, the new bridge deck is resistant to corrosion caused by effluent and produces tight joints. The result is also more visually attractive.re.

Learn more about platforms and GRP fibreglass for wastewater and chemical plants.