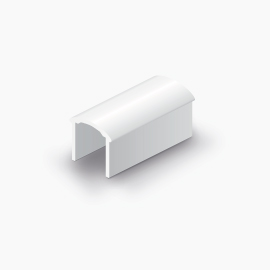

With our GRP handrail profiles you get a number of unique advantages in one product namely high strength, low weight as well as corrosion and chemical resistance. This makes our GRP handrail profiles a cost-efficient alternative to traditional materials, such as steel, aluminium and timber handrail, and are often used to ensure a safe passage for railing, stairs, staircase, bridges, walkways and platforms.

Are you looking for a safe and cost-efficient handrail profile, then take a look at our GRP handrail components. With a excellent durability and a maintenance-free material, our fiberglass handrail profiles have along life expectancy even under harsh conditions like contact with process water, a number of chemicals, salt or chlorinated water as well as humid environments. Is your location exposed to corrosion, then GRP handrail profiles are at match.

Furthermore, the low thermal conductivity of our GRP handrail profile allows a warm feel of the handrail even in temperatures below freezing point. This too also helps to ensure your safety. Other advantages include:

Learn more about the advantages our handrail profile here

At Fiberline Building Profiles, we have a wide range of handrails and stair parts in GRP. In our webshop you can see the needed length, find prices and buy directly.

Our GRP handrails for stairs and walkways are rust-proof and durable, even in demanding and corrosive conditions. They are therefore used extensively in outdoor locations, as well as for industrial purposes, cooling towers, staircase, swimming pools and offshore.

Our fibreglass handrails and supports have the same great strength as steel but are low in weight – they are only a quarter of the density of steel, which gives them a light weight and makes them easier to install and handle on site. This also means that great weight savings can be achieved on the finished structure, e.g. stairs, platforms, access walkway etc.

At Fiberline we have more than 40 years of experience with fibreglass solutions for building and industry. Our company also possess many of the highly sought-after international certifications which is not only your guarantee for high quality every time you buy our products but also makes it easy for you to use GRP for your next building project. One partner - all the certifications. Learn more here

Do you need help with our products or advice on future constructions, find our opening hours here and contact one of our employees if you have further questions or enquiries.

Fiberline is one of the world’s leading suppliers of intelligent composite profiles made of glass fibre. These profiles have been making a considerable difference to our customers in construction and industry for over 40 years. When doing business with us, you get a strong partner:

You can always find our most popular geometries available for ordering on our webshop, whenever it suits you – it is always open. We have fast delivery and a wide range of gratings and handrails to fulfil your need.

Do you need help with our products or advice on future constructions, find our opening hours here.

Please contact one of our employees if you have further questions or enquiries.

Working with fibreglass is very much like working with hardwood. A circular saw or jigsaw is ideal for ensuring a straight cut. Diamond-coated blades should be used for larger batches. The diamonds make the blade last longer. Remember to grind and deburr the cutting surfaces. You can read more about cutting speeds by watching our how-to video to see how easy it is.

You can use the same tools as in case of hardwood. However, we recommend that you employ a circular saw or jigsaw, as well as a vibration-free base for ensuring a straight cut. Diamond-coated blades should be used for larger batches, as the diamonds make the blade last longer. You can read more about cutting speeds by viewing our how-to video to see how easy it is.

When you are cutting or sawing fibreglass, we recommend that you employ diamond-coated blades. Watch our step-by-step video tutorial to find out the appropriate cutting speeds and best cutting and assembly practices. A diamond-coated blade ensures a longer economic life span than regular blades. You can also use a circular saw or jigsaw, as well as a vibrating free table for ensuring a straight cut. You should always follow the applicable local safety requirements, e.g. safety googles, mask and ventilation.