The choice of reinforcement is important for the properties of the profile, including mechanical properties such as strength and stiffness.

The orientation of the reinforcement is also of great importance to the properties of finished products as regards load-carrying capacity.

Profiles manufactured by Fiberline are a combination of various types of roving and different types of complex weaves and mats.

Structural profiles are for example often subjected to loads that are transversal to the length of the profile (i.e. transversal to the direction of pultrusion), and these profiles must often be capable of resisting pull-out loads from bolts etc.

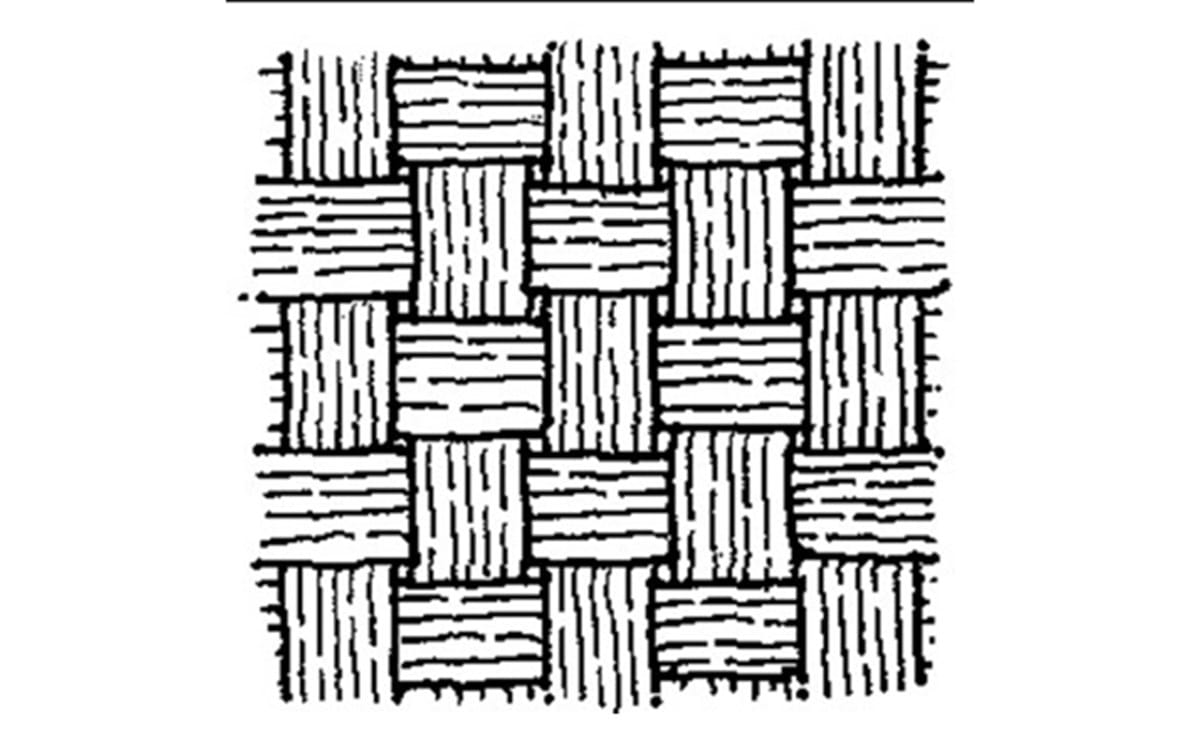

Not only unidirectional roving is therefore used, but also roving in which some of the fibres are oriented transversely. In addition, mats and weaves with different fibre orientations are used. Mats and weaves with fibre orientations of between 45° and 90° contribute primarily to improving bolt pull-out strength and mechanical properties in the transverse direction.

The combination of roving and mats can be tailored to the requirements made to the individual profile based on the needs of the customer.

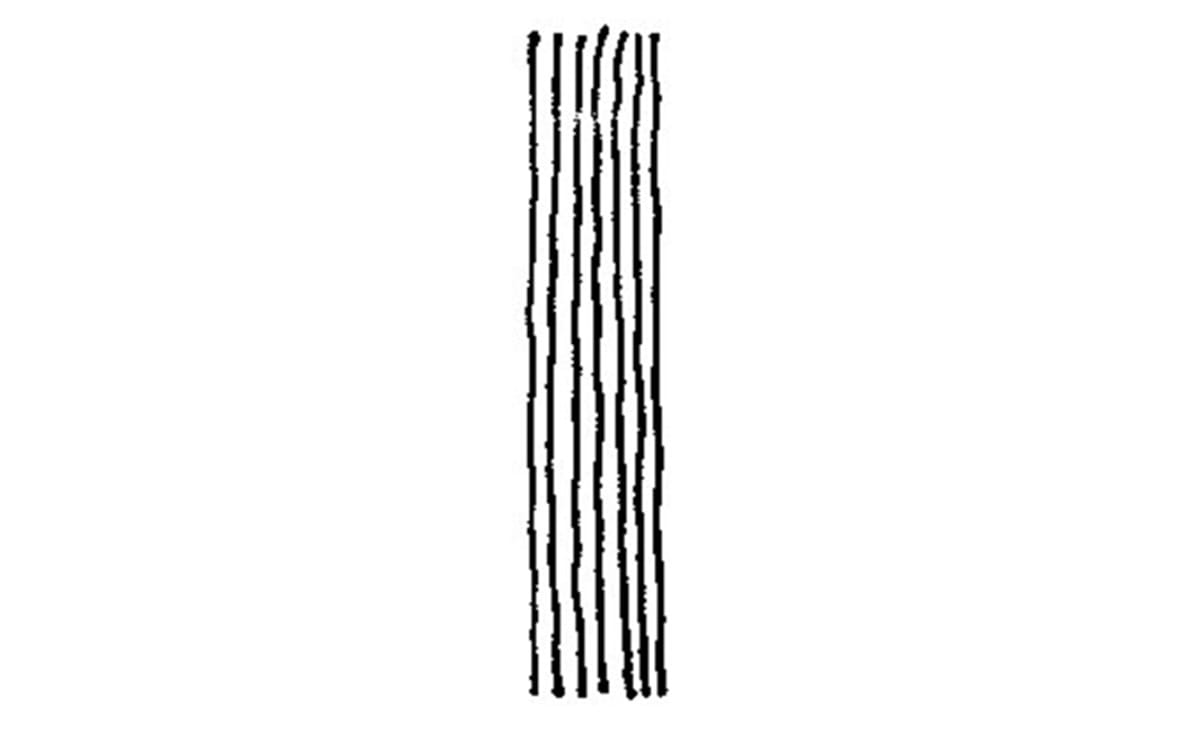

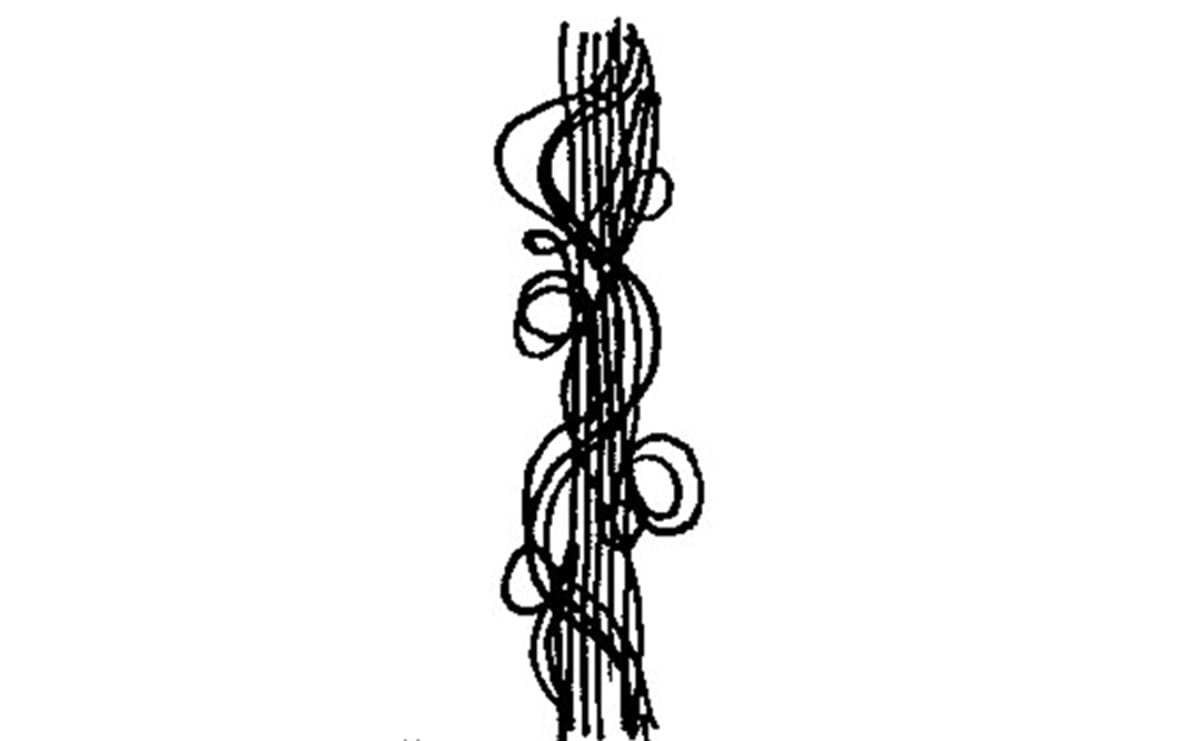

Types of rowing

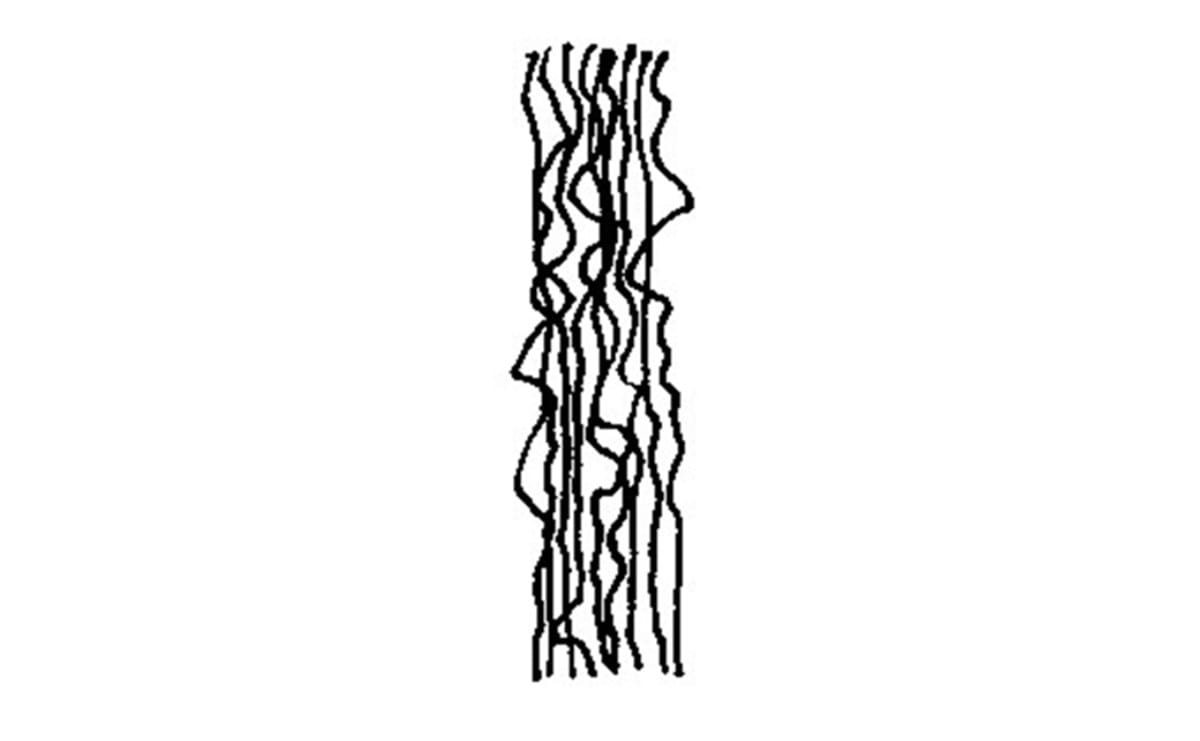

Type of mat

If a profile is to be located in a corrosive environment an “surfacing veil” is used. This can be thin fibreglass matting, thin thermoplastic polyester matting or acrylic matting which is placed on the entire profile surface to protect the glass fibres against corrosion and subsequent deterioration of the mechanical properties of the profile.

The pultrusion process necessitates that a certain number of the fibres be oriented in the direction of pultrusion, but the reinforcement can otherwise be structured in innumerable ways depending upon the load.

The role of the matrix in a composite profile is partly to bind the reinforcement together, and partly to keep the reinforcement correctly positioned in relation to the cross section with a view to optimal utilization of the mechanical properties. The type of matrix also determines properties such as corrosion resistance, electrical insulation properties, and fire and temperature resistance.

The following three types of matrix are fundamentally well suited to the pultrusion process: polyester, epoxy and phenol.

Polyester is the most frequently used matrix as it produces a composite with good all-round properties.

Unsaturated polyester can be divided into three main groups: orthopolyester, isopolyester and vinylester. Compared with orthopolyester, isopolyester increases impact resistance, provides greater flexibility, and increases resistance to temperatures. It also increases corrosion resistance.

Vinylester has even better corrosion resistance and thermal properties. Since vinyl ester has greater elongation properties than ortho- and isopolyester, it also provides a composite with better impact resistance and improved fatigue properties.

Epoxy is used primarily for carbon-reinforced profiles, giving composites better fatigue and mechanical properties. Epoxy is more resistant to thermal influences and has better electrical properties.

Phenol is used when there are requirements to high fire resistance, temperature resistance, low smoke generation, and flame retardation when subjected to fire.

“Additives” is a general term used for agents which are added to the matrix. Depending upon their purpose, additives can be divided into three fundamental groups: price-reducing additives, process-related additives and function-related additives. While the purpose can vary, additives will always influence the corrosion resistance of profiles, as well as their mechanical and fire-technical properties.

Process-related additives are substances that have beneficial effects on the pultrusion process and on the properties and appearance of a cured profile. One example is the “low-profile additive” used to avoid excessive shrinkage during curing of profiles. The additive prevents formation of hair-line cracks in surfaces, while increasing profile resistance to corrosion and improving fatigue properties. It also gives profiles more exact geometric tolerances and lower internal stress.

Function-related additives have a beneficial effect in relation to the use of a finished profile. One example is the adding of pigments. Adding of fire retardants is another example. The latter are added to obtain self-extinguishing properties and to retard flame spread.

Of course, function-related additives can also be added in amounts so large as to degrade the mechanical properties of a profile.

See also the Fiberline Quality Codex on page 0.10-0.11 of the Fiberline Design Manual.

The sole function of price-reducing additives is to fill out the form of a profile, and adding such additives enables reduction of more expensive reinforcement and matrix materials. It is thus possible to reduce the price of the finished profiles accordingly. Profiles have significantly poorer mechanical properties when the amount of reinforcement is reduced. Moreover, most types of price-reducing additives also result in profiles with lower corrosion resistance and diminished resistance to most chemicals.

*Often referred to as “fillers”.