Fiberline Building Profiles A/S and CTS Bridges

HD plank, handrail profiles

For more than 25 years CTS Bridges of Huddersfield, West Yorkshire, England, have been building bridges made of steel and timber. Now, CTS also builds bridges made of FRP composite - most recently in summer 2013 when the company installed two bridges in Scotland using somewhat unconventional means.

When CTS Bridges was established in 1988 FRP composite was a material that most bridge builders had probably heard of, but which was hardly considered a serious alternative to conventional materials. Today things are different. With its light weight and high strength, FRP composite has shown its advantages in many other applications. We were therefore delighted that CTS recently opted to add Fiberline's products to their range – and still more delighted that they have already designed, manufactured and installed several bridges using Fiberline profiles; these include two bridges at Earlsburn Reservoir in Scotland.

Earlsburn Reservoir is a remotely situated reservoir operated by Scottish Water. The reservoir lies a long way from the nearest main road and this begged the question of, how two replacement service bridges could be transported to their final destination.

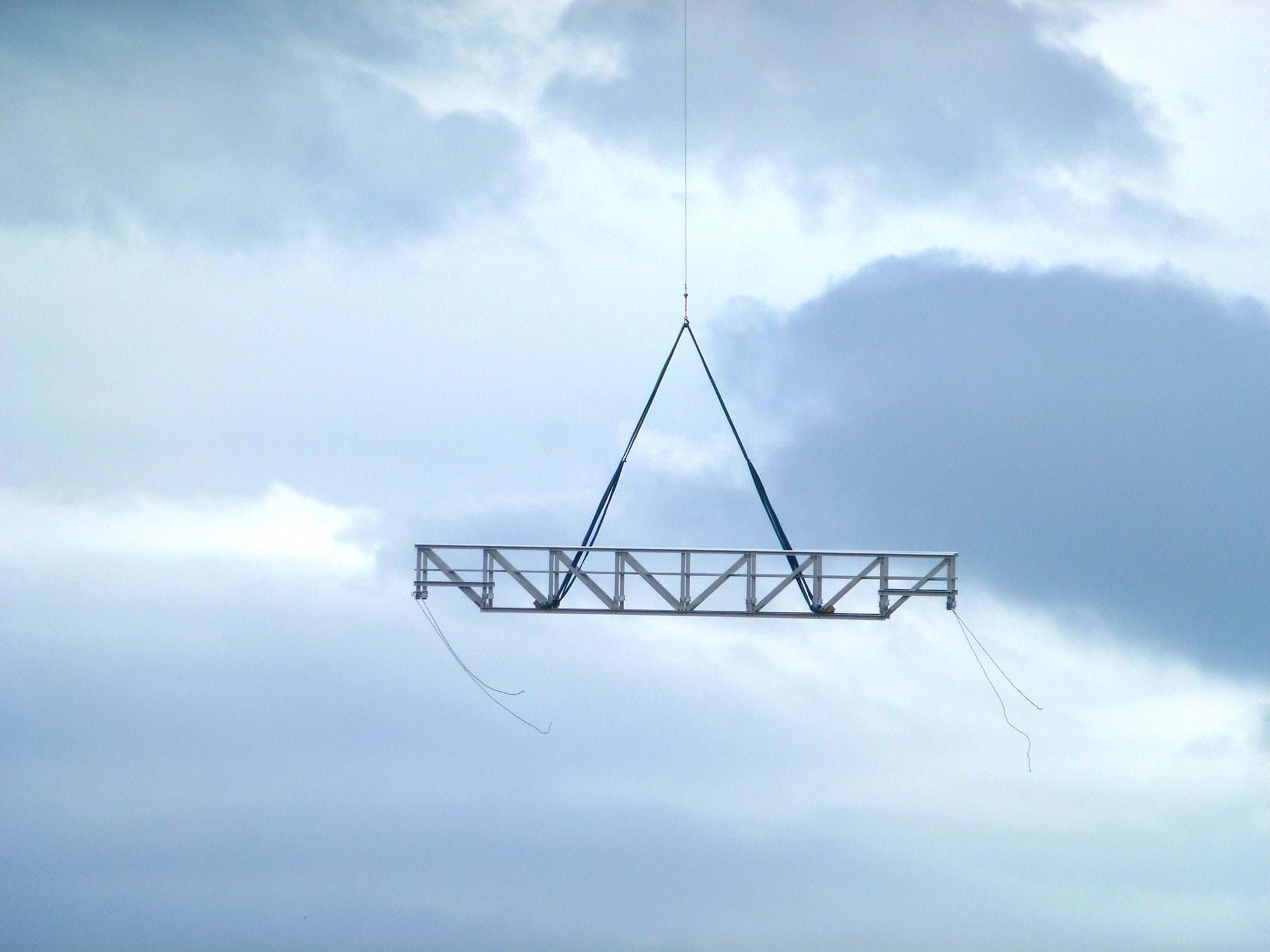

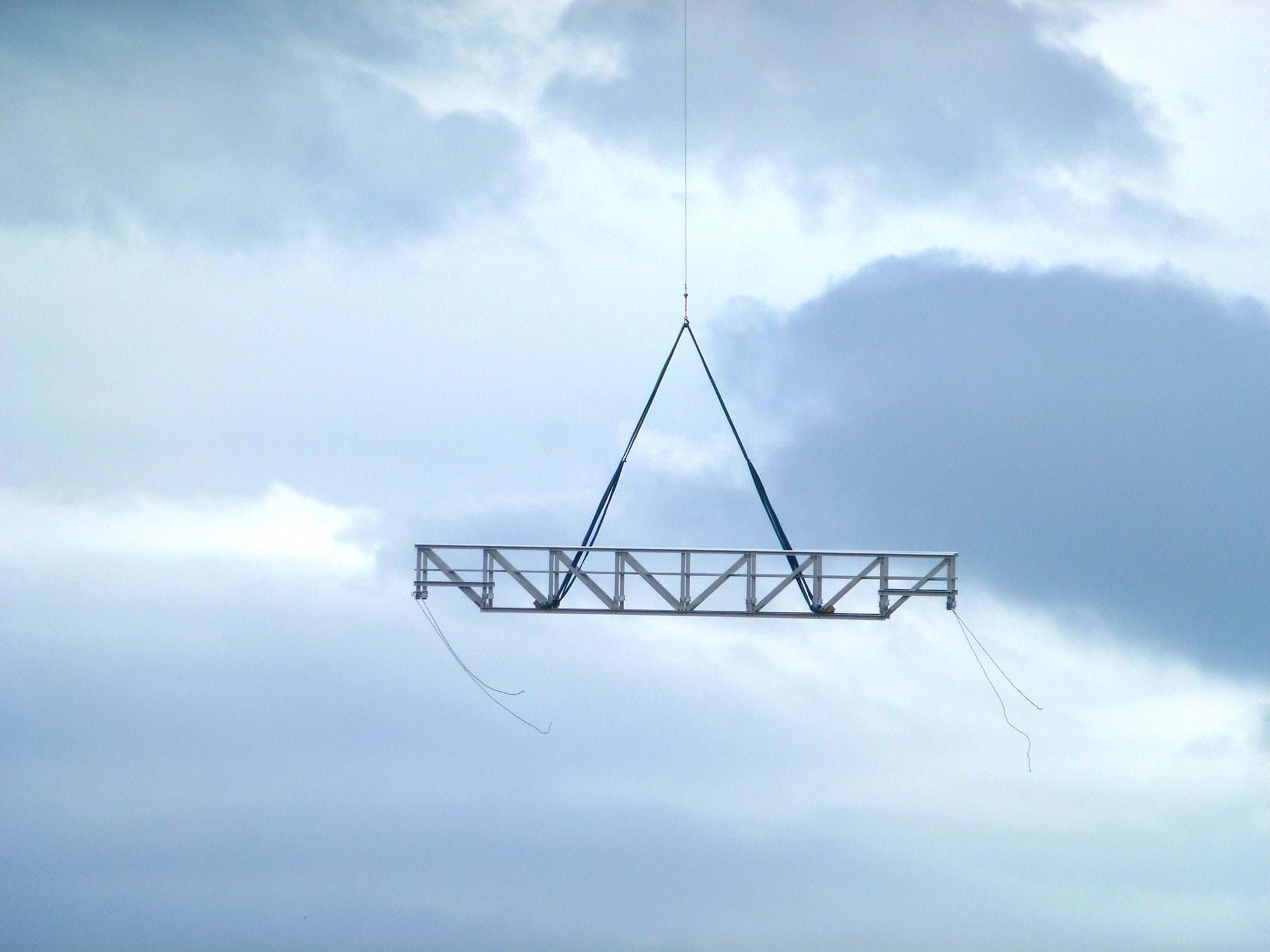

Simon Newby, Director of CTS, takes up the story:"Difficulty of access to Earlsburn Reservoir made it impossible to transport the bridges by existing roads or get a crane to the site; flying the bridges into position with a helicopter became an economically viable solution for our client. With this in mind, we limited the weight of the structures at the design stage so that the assembled trusses could be carried with a relatively small single-rotor helicopter."

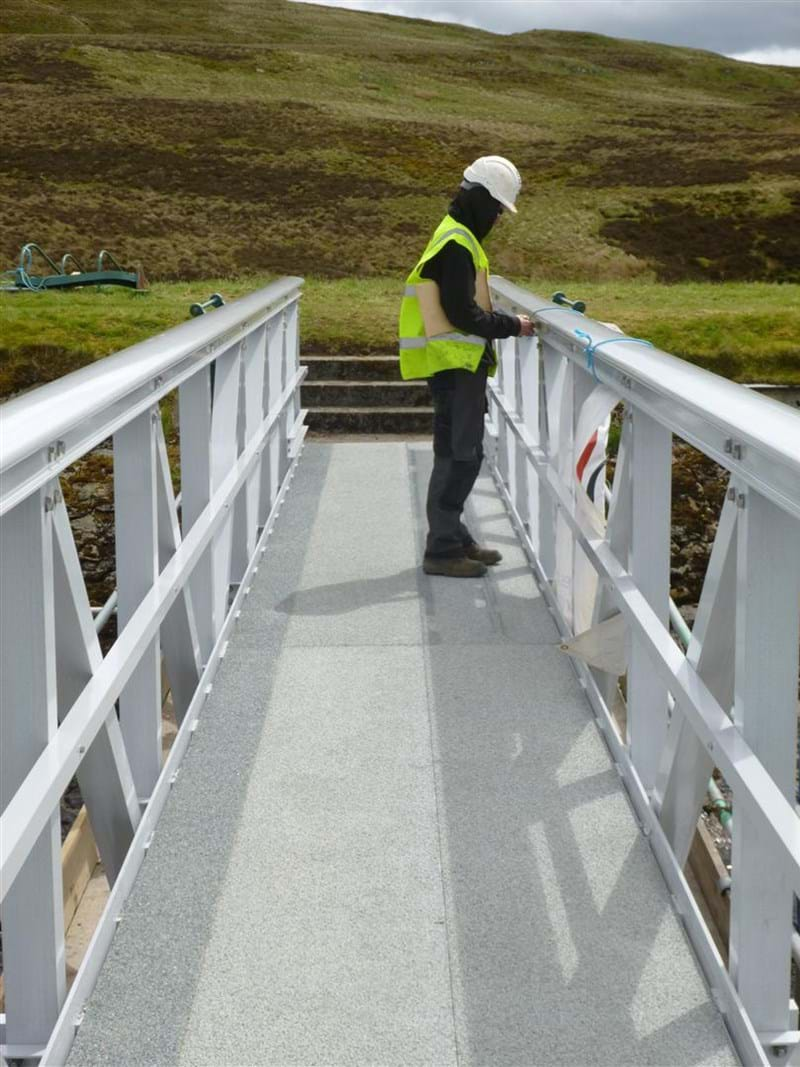

The superstructures span up to 13.5 m and both weigh less than 850 kg, comparable steel framed structures would have weighed three or four times as much. The installation took just three hours, after which CTS laid a FRP composite deck consisting of Fiberline HD planks.

"The most important attribute of these bridges was their light weight, which enabled use of this unusual method of transport and installation. But the durability of the construction material was also an important factor. The bridges are located in a damp and wet environment. The pre-existing steel bridges had suffered with corrosion and the client wanted the replacements to be constructed from a material that could withstand harsh weather conditions without rusting or ongoing paintwork maintenance" continues Simon Newby.

CTS found exactly what they were looking for at Fiberline, but there is still some way to go before customers specifically request materials that differ from the traditional options.

According to Simon Newby a greater awareness of the many useful properties of FRP composite is a key to still greater demand:

"We need enlightened clients who can see the whole life costing benefits of FRP structures and find situations where their light weight offers installation advantages. Gradually, as more bridges made of FRP composite are installed, customers will become aware of the possibilities. We have to be good at drawing attention to the benefits of composite, for instance we can provide much larger economic spans than we can in timber, but the Fiberline profiles can be machined and drilled with similar ease to timber. Additionally, FRP composite doesn't need painting as of course it never rusts."

If you would like to know more about lightweight, strong and durable bridge solutions, contact Fiberline today

Learn more about fibreglass composite bridges.