Danish element manufacturer Amovido has set out to explore more long-lasting, sustainable options to traditional building materials, setting their sights on fibreglass with blown-in PUR as an interesting product for insulation.

When using traditional building materials, problems with moisture and mould can often arise in Denmark’s cold, damp climate, and the building process is both time-consuming and hard on the environment. That is why Amovido wants to look at more long-lasting, sustainable materials for the future of housebuilding – built using elements.

Element testing in aggressive environments

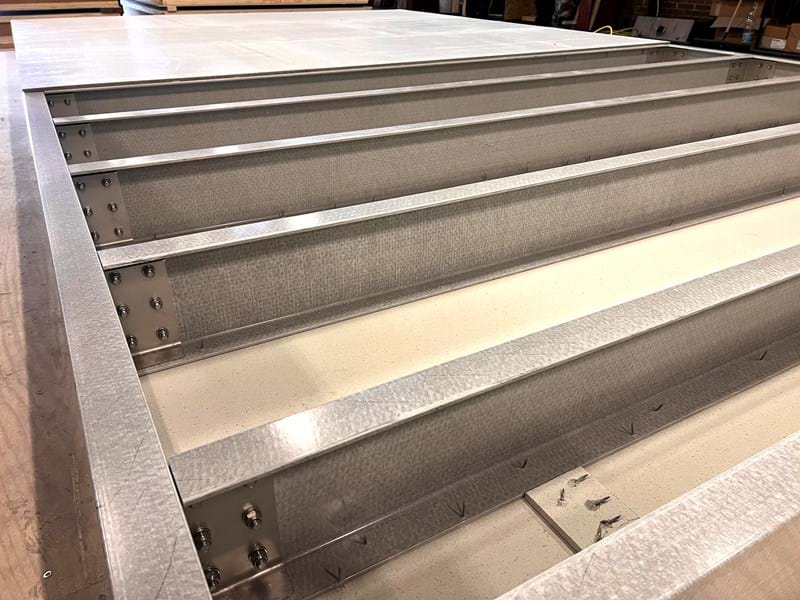

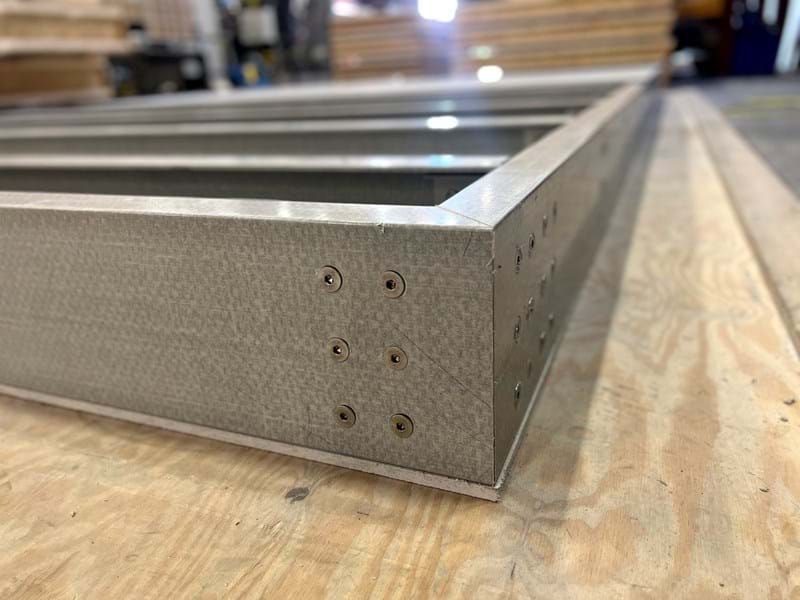

The company is currently testing a new concept comprised of a fibreglass floor built in the form of load-bearing elements with fire separation. Instead of traditional insulation, Amovido uses PUR insulation that is blown directly in to the element itself.

In the test phase, the elements are carefully inspected for moisture accumulation and condensation in aggressive environments close to where they are produced.

"We have a number of sustainability initiatives we want to pursue for the moisture-sensitive elements we make. We are therefore in the process of exploring the market for alternative products," says Mikkel Runøe, Managing Director of Amovido A/S.

Buildings can be sealed up more quickly

Amovido is the frontrunner within modular element construction in Denmark. Using their patented solution, companies can produce highly insulated, fire-safe and prefabricated elements which make it possible to build more efficiently. At the same time, there is also a focus on the green transition in construction.

The benefits are clear:

- PUR is significantly more insulating than traditional insulation and is compatible with the green agenda in terms of its insulation thickness.

- Fibreglass with blown-in PUR has a very long life time.

- The elements can be taken down in blocks and reused in other buildings.

- Element construction can shorten construction time – and tradespeople can begin indoor work sooner.

"Our customers want a highly insulated wall without the need for vapour barriers and without having to pay a fortune. And they want a house that can be sealed up fast. I have very high hopes for this and certainly expect it to be a product that we will be able to use," says Mikkel Runøe.