We have gathered answers to the most frequently asked questions about working with our fibreglass products here. Hopefully, you will find what you are looking for, and if not, we are ready at the telephones to help you.

- How do I paint fibreglass?

Fibreglass is easy to paint, but the process depends on both the solution in question and the desired finish. Here are our recommendations when it comes to painting fibreglass.

- How do I glue fibreglass?

Gluing fibreglass depends on the type of job involved, but it is usually very easy to do. Watch our How to video about gluing here

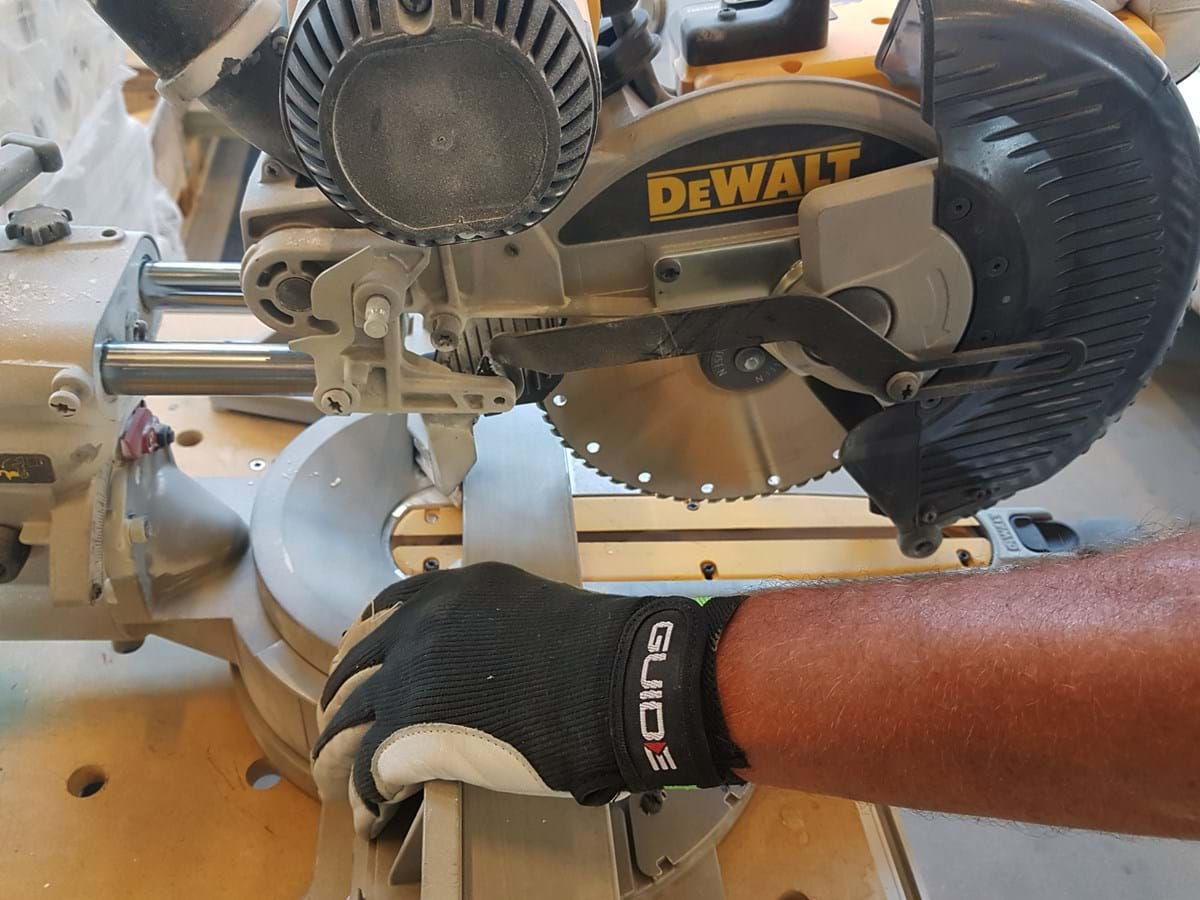

- How do I cut and saw fibreglass?

Working with fibreglass is very much like working with timber. A circular saw or jigsaw is ideal for ensuring a straight cut. Diamond-coated blades should be used for larger batches. The diamonds make the blade last longer. You can read more about cutting speeds and watch our how-to video to see how easy it is here in our How to video

- How do I drill into fibreglass?

Drilling into the profiles is relatively straightforward. An ordinary metal drill bit should be used to drill individual holes or small numbers of holes.

The use of a special drill bit is recommended for larger numbers of holes. This will ensure that the hole rims are clean and free from burring. A spoon bit and centre bit can be used to drill large holes. You can find lots of advice about drilling here

- How do I insert bolts and screws into fibreglass?

It really depends on what it is that you need to mount or fit together. We have provided the example of a square tube, which we recommend should be fitted using a sleeve, insert or washer. It is the same idea for many other types of mounting, but if you are in any doubt you can always get in touch for technical advice. See how to mount a square tube on a stair in our video here

- How do I mount fibreglass?

Mounting naturally depends on the type of structure that is being assembled. We have provided an example of how to mount a square tube onto a staircase. Watch the video here

- How do I grind and deburr fibreglass?

Our fibreglass profiles can be ground using sandpaper. For larger tasks, however, we recommend using a belt sander.

- How do I turn fibreglass?

For turning, we recommend using carbide plates with speeds of up to 400 m per minute. A top rake of 10–15° will yield the best results. The feed rate and cutting depth will depend on the machine used, but is typically between 0.05 and 0.5 mm/rev. Depending on the machine and the set-up, the depth of cut can be up to 10 mm. Using rounded tool bits and air or liquid cooling results in the best surface finish. Turning can also be done with a rotating diamond milling cutter in the tool holder.

- How do I mill fibreglass?

A diamond milling machine should be used for milling. We recommend a top rake of between 5° and 15° and speeds of up to 1,000 m per minute for the best results.

Feeding can be up to 0.5 mm/rev. Too heavy feeding will cause unwanted heating of the surface and gives less satisfactory results.

- What about punching, threading and waterjet cutting?

Punching, threading and waterjet cutting can be used when working with fibreglass. However, it depends very much on the type of work involved and the machinery available. Please refer to our recommendations or contact us if you would like further details.

- How do I work with a HD Plank?

Glass-fibre reinforced polyester (GFRP) is a hard material, but it is as easy and fast to work with as timber. We recommend that you use diamond-coated tools, such as cutting blades. You can now buy diamond-coated blades at any hardware shop. Watch our how to video here

- How do I install HD and MD Planks?

Our planks can be bolted, pinned or glued to the substructure. Fiberline has developed special fittings that make assembly easier and faster. All of these fittings are made of acid-resistant steel. Please give us a call if you are in any doubt about how to install your particular solution.