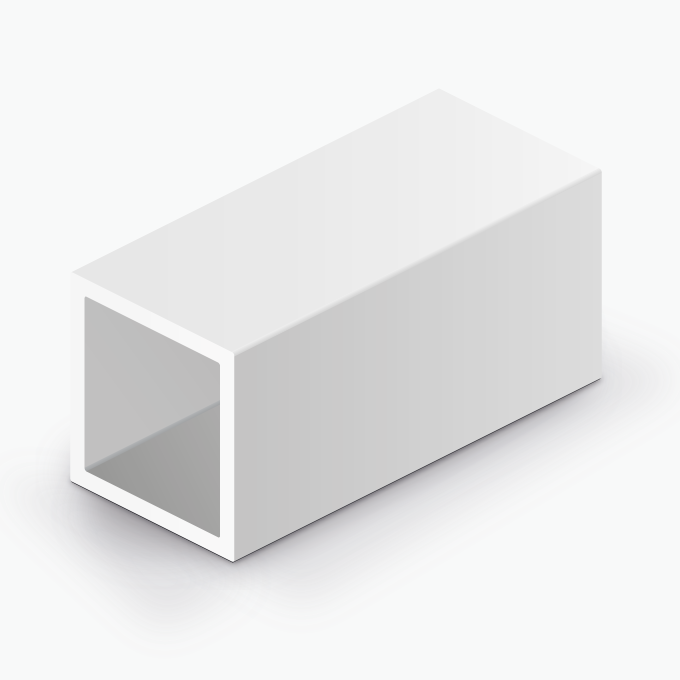

Our GRP square tubes combine a number of unique advantages such as high strength, low weight and high corrosions resistance, which provides you with a cost-efficient alternative to concrete, steel, aluminum and wood.

Our hollow grp rods have the same great strength as steel but only a quarter of the density. This helps you to reduce the weight of the entire structure. The low weight also enables an easy to work with-solution during machining, transport and installation.

Other benefits includes:

Find the 10 most important advantages of our fibreglass products here

The fiberglass tubes have an elastic modulus of 23,000 –28,000 MPa, which ensures excellent rigidity and makes the profiles particularly well-suited to construction tasks that require both great strength and low weights. Therefore, our grp tubes find use in constructions like:

Learn more about standard solutions which provides you with a well-tested and competitive construction

The fiberglass square tube is primarily designed for transferring compressive loads and is therefore suitable for supporting structures such as columns and parapets for handrails in railing systems, stairs and corridors as well as in cooling towers. Explore the length, range and sort of our fiberglass tube programme here

The GRP/fiberglass square tubes come in many different sizes – both profiles made to orders and profiles we sell from stock on our webshop. On our website you will find different services, among others cutting standard profiles to desired length, customer account, search, tutorials, and sale in Outlet . Visit webshop and outlet to see availability and order today.

Our fiberglass products have several international and highly sought-after certifications, among other, within the construction, offshore and railway sectors. Together with non-conductive and lightweight properties this makes our profiles especially suitable for constructions near the railway lines. Find all application areas here

Our fiberglass square tubes combine several advantages, making them a cost-effective alternative to traditional materials such as concrete, tree, and aluminium. This makes the grp rods ideal for sustainable building, industry and construction of the future for.

Here on the page you will find a wide range of fiberglass tubes and hollow square tube in different lengths and for different tubing applications. Search our webshop to find the right profile and length for your project. Order today

You can find our most popular geometries available for order on our webshop when it suits you, 24/7. If you need more fiberglass square tubes, please do not hesitate to contact us. We have more than 40 years of experience with GRP tubes for construction and industry, so we are pretty sure we can help you too. Find our opening hours here.

If you like to learn more about how we produce our products, find more about pultrusion here

Fibreglass is easy to paint, but the process depends on both the solution in question and the desired finish. First, you clean the profile of all grease and dust. If you want a higher quality finish, we recommend that you then prime the profile. Subsequently, you sandpaper the profile after priming to remove any fibreglass fibres that has risen. Finally, you paint the profile in the colour of your choice. We recommend using two-component polyurethane paint with a low thickness of between 40-60 μ dry. See our step-by-step tutorial here.

We recommend that you spray paint fibreglass surfaces rather than brush or roll to achieve the smoothest and most even finish as an end result. However, we recommend that you first clean and prime the profile before you paint it in the colour of your choice. We recommend using two-component polyurethane paint with a low thickness of between 40-60 μ dry. The applied method may vary depending on both the solution in question and the desired finish.

See our step-by-step tutorial here.

Fibreglass has a long effective life span even without any paint and even when its exposed to unfavourable weather conditions and wind all year round. This is because of the unique durability of the material. If you want to paint the profiles, the durability obviously depends on what kind of paint you choose.

As a rule, we use two-component polyurethane paint with a low thickness of between 40-60 μ dry. Namely, it ensures that the appearance of the profiles remains unchanged over time.

See our step-by-step tutorial here.