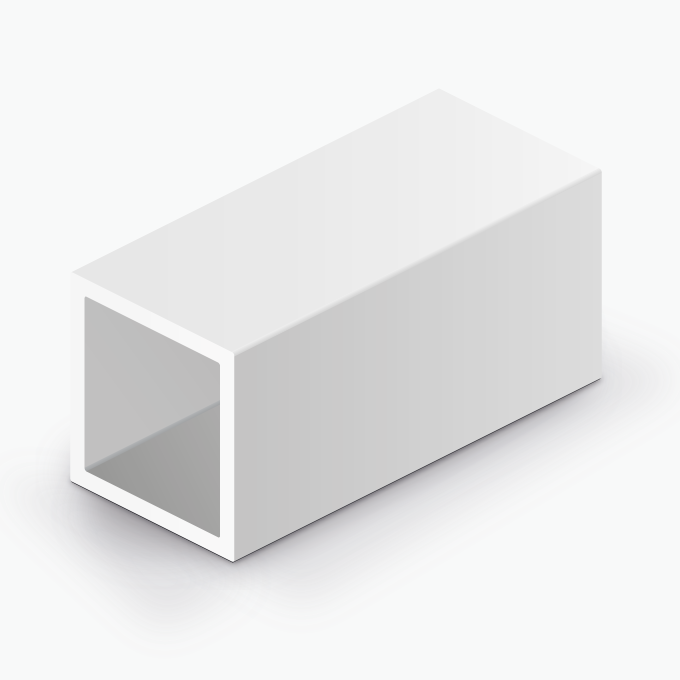

Våra fyrkantsrör har samma höga styrka som stål, men bara ¼ av densiteten, vilket ger viktbesparingar på den samlade konstruktionen och enklare hantering vid montering.

Det fyrkantiga ihåliga röret är ett kostnadseffektivt alternativ till stål eftersom det inte rostar även under de mest krävande och korrosiva förhållandena offshore eller i simhallar. Här har profilerna fortfarande en lång livslängd och behöver därför inte bytas ut eller underhållas så ofta.