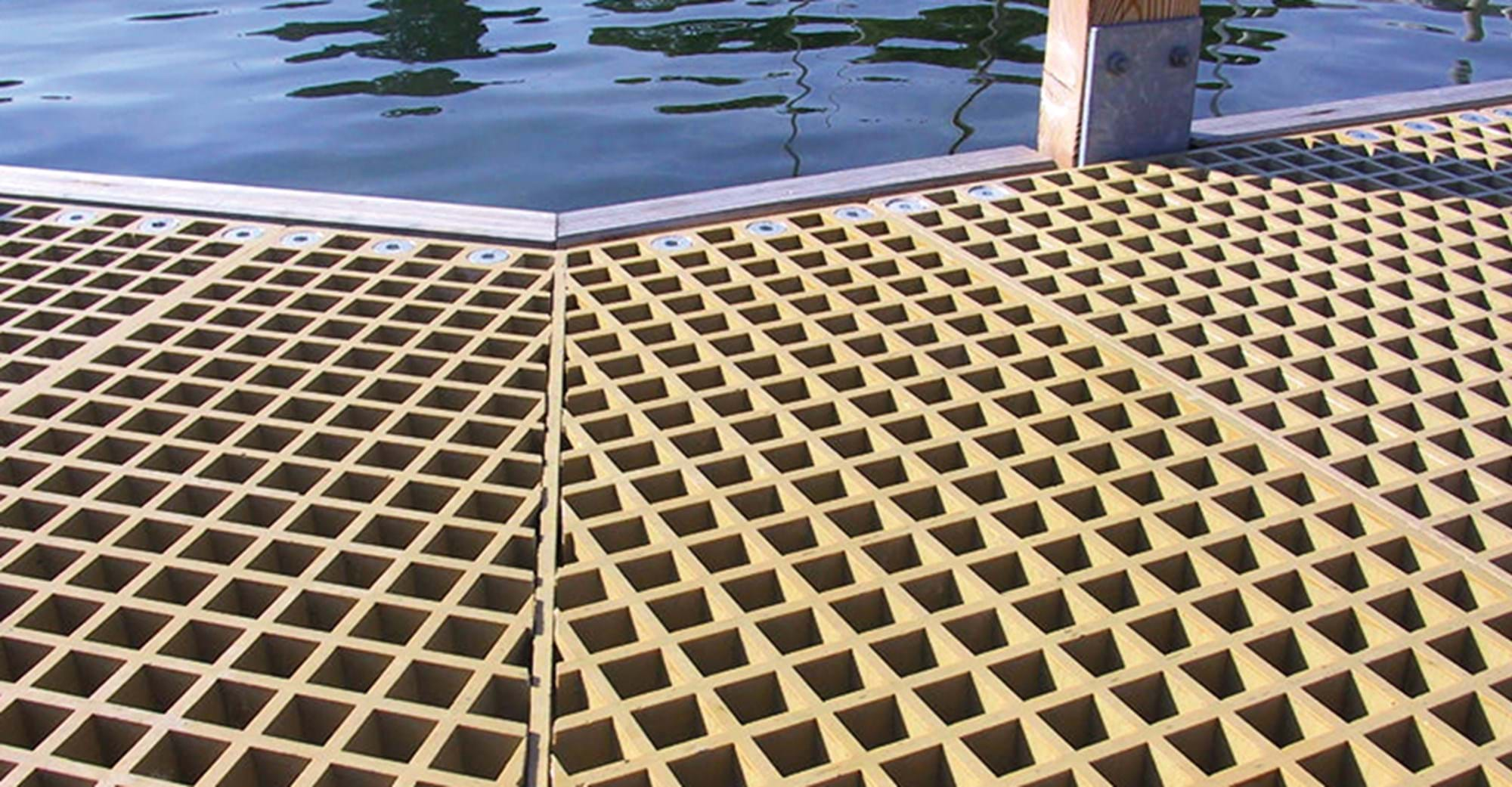

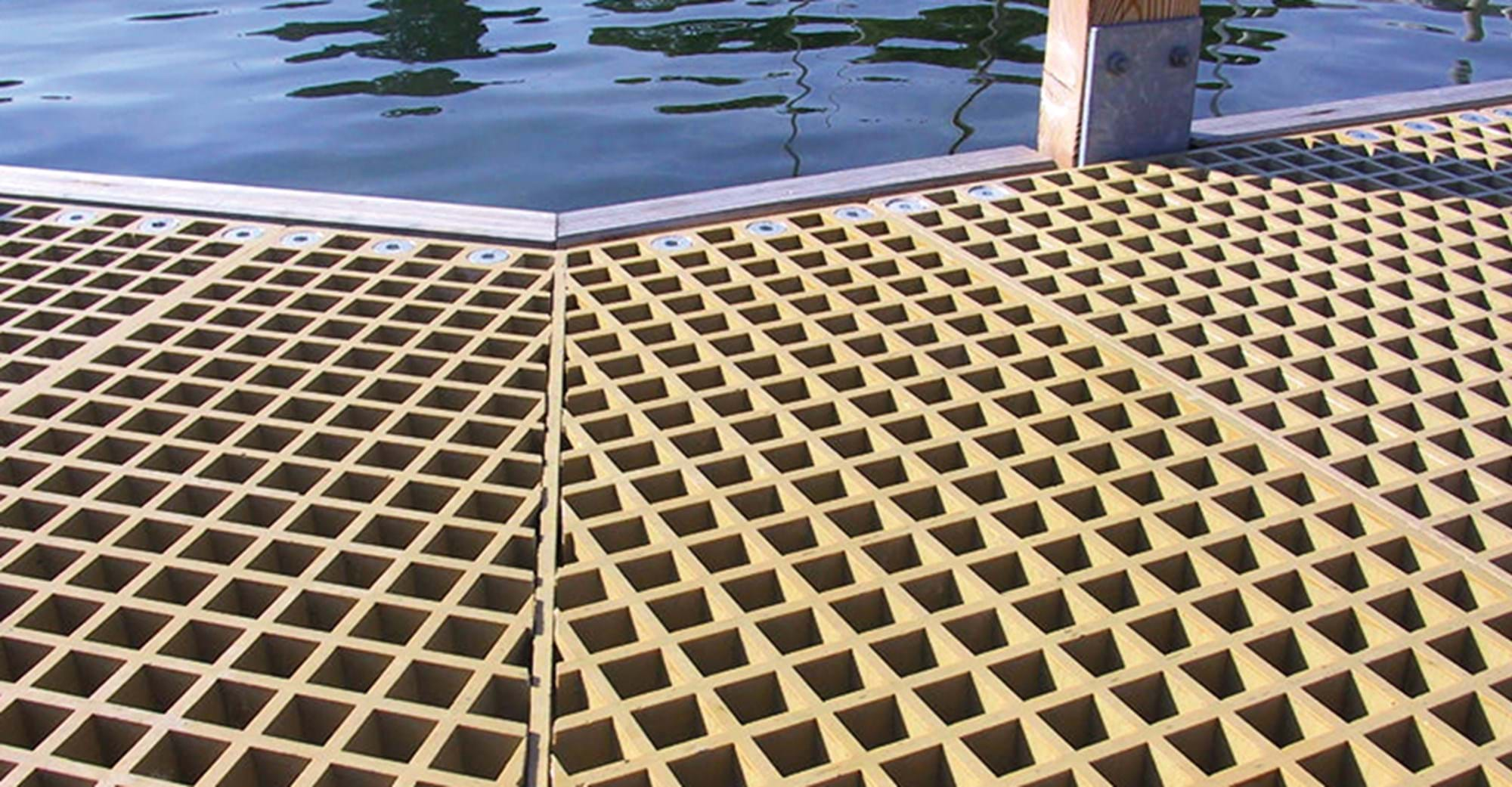

Before choosing your next fibreglass grating, there are a number of factors that you need to clarify, including requirements for deflection, tolerances, grating height and span. If the grating is to be placed in a gutter or often removed, there may also be requirements for the weight. In addition, the application area also determines which resin quality to use, e.g. Vinyl Ester, isopolyester or orthopolyester. Finally, the appearance of the grating, e.g. with smooth edges, can have an impact on the end customer and thus be decisive for the dimensions of the grating. On this page you will find more information about our grates. You are also welcome to contact us for a dialogue about your next project.

The choice of resin largely depends on where the gratings are to be used. Our two most used materials are Ortho polyester and Iso polyester.

Ortho polyester: Moderate corrosion resistance without fire-retardant substances. Suitable for contact with salt water and for light industrial use. Read more here 'Ortho' (English)

Iso polyester: Superior corrosion resistance with improved fire-retardant properties. Suitable for environments with aggressive chemicals and high temperatures. The gratings are DNV-approved for use on ships. Read more here Isophthalic Polyester (English)

We also have a limited stock of gratings in Vinyl Ester, which are therefore typically produced on demand. Read more here: Vinyl Ester (English)

Here you'll find useful information about our gratings, ready to print out or attach to your project file.

Data Sheet for gratings - incl. load tables

The gratings' appearance (such as gratings with smooth edges) can be of significance to the end customer, and may therefore determine their overall dimensions.

The dimensions of the table can be combined freely in longitudinal(L) and lengthwise(B) directions. Note however the basic dimensions of the chosen grating panel.

Gratings cut to dimensions as listed in the below table have smooth edges (i. e. no "fingers"). Cutting tolerance +2/-5.

The outside grid of whole panels is 3 mm smaller than the inside grid.

Gratings cut to smooth edges, where the inside grid is used, is therefore 3 mm smaller than listed in the table. Allowances were made for this in the cutting tolerances.

Grid size 20 x 20 / 38 x 38 mm: |

|||||

| 42 | 652 | 1261 | 1871 | 2481 | 3090 |

| 81 | 690 | 1299 | 1909 | 2518 | 3128 |

| 118 | 728 | 1338 | 1947 | 2557 | 3166 |

| 156 | 766 | 1376 | 1985 | 2595 | 3204 |

| 195 | 804 | 1414 | 2023 | 2633 | 3243 |

| 233 | 842 | 1452 | 2061 | 2671 | 3281 |

| 271 | 880 | 1490 | 2100 | 2709 | 3319 |

| 309 | 918 | 1528 | 2138 | 2747 | 3357 |

| 347 | 957 | 1566 | 2176 | 2785 | 3395 |

| 385 | 995 | 1604 | 2214 | 2823 | 3433 |

| 423 | 1033 | 1642 | 2252 | 2862 | 3471 |

| 461 | 1071 | 1680 | 2290 | 2900 | 3509 |

| 499 | 1109 | 1719 | 2328 | 2938 | 3547 |

| 537 | 1147 | 1757 | 2366 | 2976 | 3585 |

| 576 | 1185 | 1795 | 2404 | 3014 | 3623 |

| 614 | 1223 | 1833 | 2442 | 3052 | 3658 |

Grid size 40 x 40 mm: |

||||

| 45 | 685 | 1325 | 1965 | 2605 |

| 85 | 725 | 1365 | 2005 | 2645 |

| 125 | 765 | 1405 | 2045 | 2685 |

| 165 | 805 | 1445 | 2085 | 2725 |

| 205 | 845 | 1485 | 2125 | 2765 |

| 245 | 885 | 1525 | 2165 | 2805 |

| 285 | 925 | 1565 | 2205 | 2845 |

| 325 | 965 | 1605 | 2245 | 2885 |

| 365 | 1005 | 1645 | 2285 | 2925 |

| 405 | 1045 | 1685 | 2325 | 2965 |

| 445 | 1085 | 1725 | 2365 | 3005 |

| 485 | 1125 | 1765 | 2405 | |

| 525 | 1165 | 1805 | 2445 | |

| 565 | 1205 | 1845 | 2485 | |

| 605 | 1245 | 1885 | 2525 | |

| 645 | 1285 | 1925 | 2565 | |

Grid size 50 x 50 mm: |

|||||

| 58 | 718 | 1379 | 2039 | 2700 | 3366 |

| 109 | 769 | 1430 | 2090 | 2750 | 3408 |

| 160 | 820 | 1480 | 2141 | 2801 | 3458 |

| 210 | 871 | 1531 | 2192 | 2852 | 3508 |

| 261 | 922 | 1582 | 2242 | 2903 | 3558 |

| 312 | 972 | 1633 | 2293 | 2954 | 3608 |

| 363 | 1023 | 1684 | 2344 | 3004 | 3658 |

| 414 | 1074 | 1734 | 2395 | 3055 | |

| 464 | 1125 | 1785 | 2446 | 3106 | |

| 515 | 1176 | 1836 | 2496 | 3157 | |

| 566 | 1226 | 1887 | 2547 | 3208 | |

| 617 | 1277 | 1938 | 2598 | 3258 | |

| 668 | 1328 | 1988 | 2649 | 3309 | |