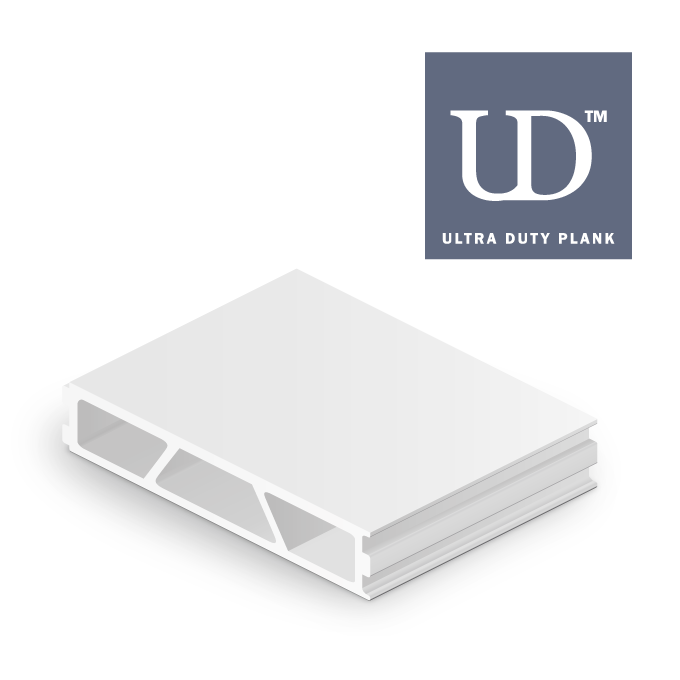

Ultra Duty Planks 80 x 333 mm

Fiberline Ultra Duty plank with CE marking

The Ultra Duty Plank is our strongest bridge decking, designed to meet the most stringent load requirements for pedestrian and cycle bridges. The UD plank reduces the weight of the structure and is easy to work with at the installation site. It is also corrosion-resistant against a range of chemicals and salt water. Asphalt or PPMA/Epoxy strewn with sand or gravel can be used as a wearing surface.

For load tables - click here

Description

Description

Fiberline Ultra Duty plank with CE marking

The Ultra Duty Plank is our strongest bridge decking, designed to meet the most stringent load requirements for pedestrian and cycle bridges. The UD plank reduces the weight of the structure and is easy to work with at the installation site. It is also corrosion-resistant against a range of chemicals and salt water. Asphalt or PPMA/Epoxy strewn with sand or gravel can be used as a wearing surface.

Application

The plank is designed for bridges with occasional traffic of vehicles up to 12 tonnes but can also be used for walkways, access roads and coverings. The UD plank can be mounted on underlying structures made of steel, reinforced concrete or fibreglass and can be fixed in the transverse or longitudinal direction by bonding with a dual-component epoxy adhesive. This results in a strong and rapid bond that lasts for many years.

Quality and standards

Our planks are certified in accordance with several accepted standards, including CE, the German aBG standard and EN13706. This is your guarantee of a high and consistent quality every time you shop with us.

Quality and standards

Quality and standards

EN 13706-3:2002

ISO 9001

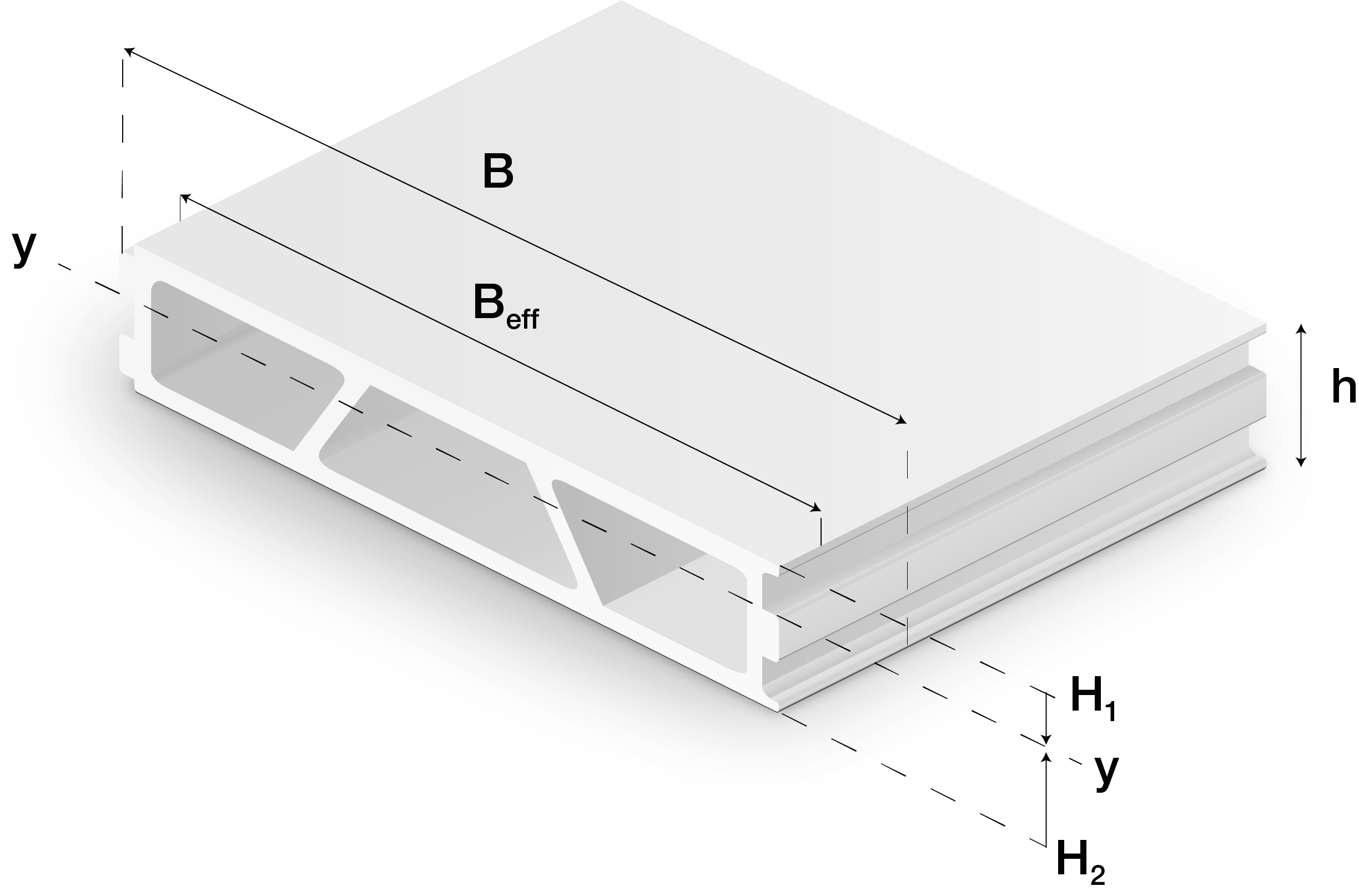

Specifications

Specifications

| Height | 80 mm |

| Width | 333 mm |

| Weight | 12.9 kg/m. |

| Moment of inertia | 7220000 mm4 |

| E-modul | 31000.0 MPa |

| Colour | RAL 9001 |

| Quality | FL Standard |