A hybrid bridge consists of several materials and is designed to utilise their different properties. Our hybrid bridge with fibreglass will typically consist of designs with a steel beam substructure and fibreglass bridge deck. Here, we utilise the rigidity of the steel to create long spans, and the durability of the fibreglass to create a corrosion-free and anti-slip bridge deck. However, it is also possible to design a construction with other materials, e.g. a substructure in reinforced concrete, aluminium or wood as well as with different types of anchoring.

Is weight an issue? If so, then the solution is fibreglass, which thanks to a density that is lower than steel (just 1/4), lets you save on the total weight of the bridge.

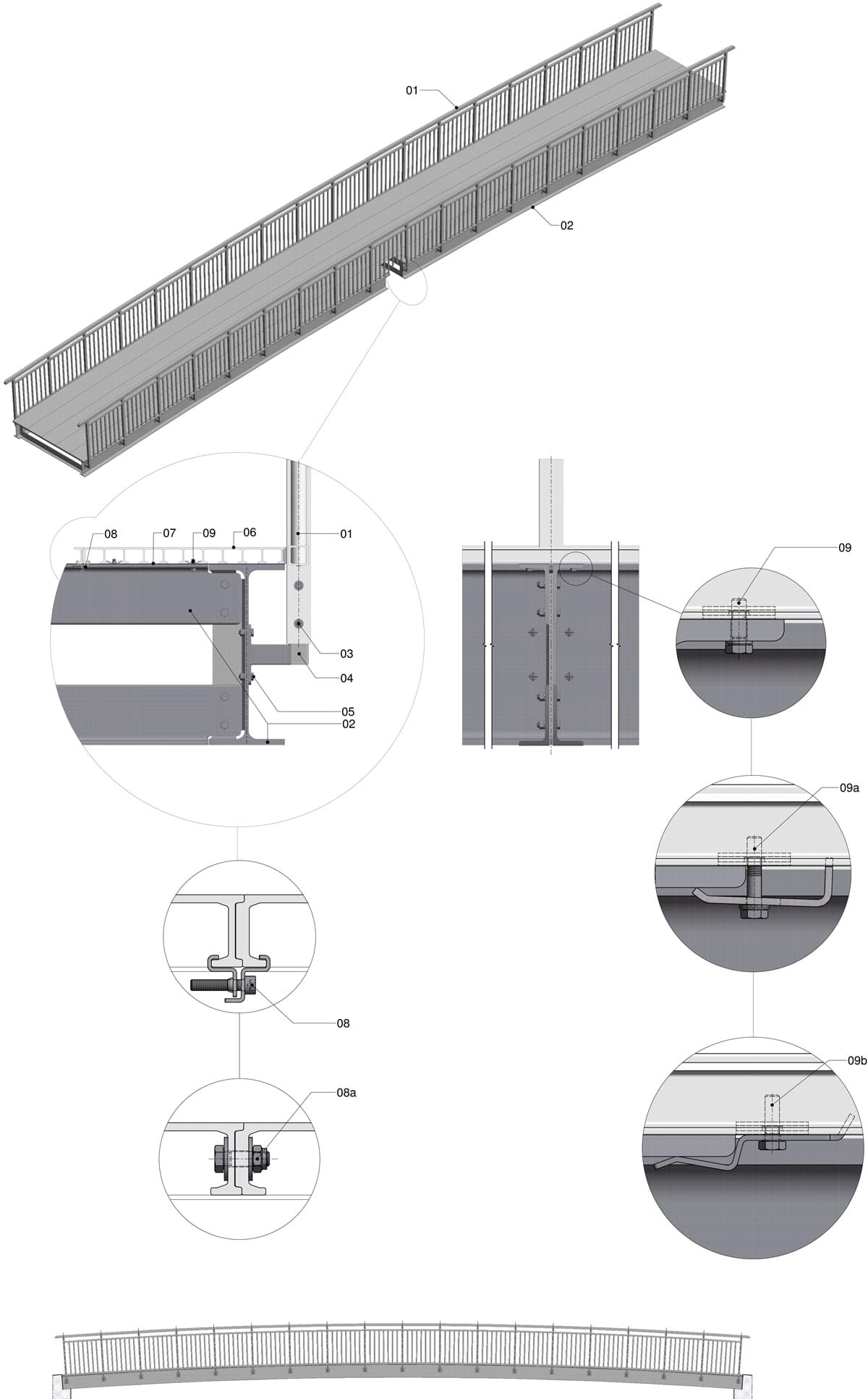

Illustration

Hybrid bridge, with main girders from IPE steel profiles. Drawings shown HD Plank with anti-skid surface. Railing are also made from Fiberline structural profiles.

1. Type 1 handrail system

2. IPE steel girders

3. Steel bolts for fastening the handrail system

4. Steel angle brackets for attaching handrail system to steel girders

5. Bolts for attaching angle bracket

6. HD Plank with anti-skid surface

7. Steel crossbeams, to be places according to load table or calculation

8. Coupling Clip, item no 149104

8a Alternatively an M8 bolt with washers can be used

9. HD Clip, item no 149100 for mounting planks to sub structure

9a HD Clamp, item no 149102 clamming planks to sub structure

9b Clip-design for maximum clamping power

Data sheet for decking

Fiberline Medium Duty Plank

Fiberline Medium Duty Plank is designed with an excellent price-performance ratio. The plank weighs only 6.58 kg/m, making it easy to handle on-site. Like other products from Fiberline, plank MD is made of GFRP. This material has noteworthy properties such as a long, proven service life as well as high corrosion resistance and strength. Fiberline plank MD is also available with anti-skid surface

Fiberline Heavy Duty Plank

The strong Fiberline Heavy Duty Plank is suitable for applications were load requirements are 5 kN/m2 and point loads are 10 kN, e.g. decks for bike paths and pedestrian bridges. Plank HD is corrosion-free and has a long service life, even under demanding and corrosive conditions, e.g. swimming pools, industry and cooling towers settings as well as offshore. Other advantages include great strength, low weight and electrical insulation. Plank HD is also available with anti-skid surface.

Fiberline Ultra Duty Plank

The Ultra Duty Plank is our strongest bridge decking, designed to meet the most stringent load requirements for pedestrian and cycle bridges. The UD plank reduces the weight of the structure and is easy to work with at the installation site. It is also corrosion-resistant against a range of chemicals and salt water. Asphalt or PPMA/Epoxy strewn with sand or gravel can be used as a wearing surface.

The advantages of a hybrid bridge will naturally vary depending on the materials you choose to use. When you choose fibreglass, you avoid rust and rot and you get a maintenance-free bridge that needs fewer inspections and with fewer associated costs. This advantage is particularly evident if the site of the bridge is near the coast or in a humid area or if it is in a location where there is a particularly high risk of corrosion.

The clear advantages of a hybrid bridge with fibreglass are:

We offer a full 6x2 meter FRP bridge solution on our website. Pre-drilled and cut to size. Ready for you to assemble.

You should choose a fibreglass bridge if you need a strong, durable and lightweight bridge design – and if you also want to save on future maintenance costs.

The hybrid bridge is well-suited for natural areas where you want to use wood, e.g. as a substructure, but also want a high level of safety and a durable solution with a long life. See how Ikast-Brande Municipality solved this challenge with a hybrid bridge in a scenic area

If you need long spans, our hybrid bridges often consist of a substructure with steel beams, after which our fibreglass planks are installed for a safe, corrosion-free bridge deck. Among others, this construction was used for one of Germany’s largest fibreglass bridges. Read more about the case here

Did you know that you can buy a complete fibreglass bridge directly in our online shop? Order a fibreglass bridge here

You can also read more about our other fibreglass bridge solutions here

We have the world’s largest online shop for CE-marked fibreglass profiles and fibreglass planks. This allows for numerous possibilities when designing a hybrid bridge. Explore the shop and order today

If you need to talk about the structure of cost in connection with your next bridge, contact our bridge experts. They areon hand to help you with your next project – contact us

At Fiberline Building Profiles, you get a cost-effective and energy-efficient alternative for your next bridge solution. We have more than 40 years’ experience with fibreglass and took part in the construction of Scandinavia’s first fibreglass bridge in 1997. It still stands as it was built, a testimony to the advantages of fiberglass in bridge-building. Our service can include design, calculations, working as well as assembly and installation.

Do you want to learn about fibreglass as a material and how we can use the production method called “pultrusion” to reproduce the same high quality every single time? Read more here

You can also read more about our approach to the environment and quality or watch a video about our company

At Fiberline Building Profiles we love to inspire others to make strong, durable and cost-effective solutions. For this reason, we have compiled plenty of inspirational material about uses and industries

We have also developed a number of standard solutions, where our GRP-products are widely used