What typifies full FRP bridges is the substructure which consists of the bridge deck and the railings all made of FRP material. Steel is used only in the form of bolts, nuts, and washers. With the standard profile program from Fiberline, it is possible to configure and build full FRP bridges up to a span of 20 meters. Full FRP bridges are usually pedestrian bridges, walking bridges or bicycle bridges with traffic loads up to 12 tons. Spans up to 10 meters are possible with a girder-substructure while spans over 10 meters require trusses. Weight of the bridges is around 60-80 kg/m2 including the anti-skid surface.

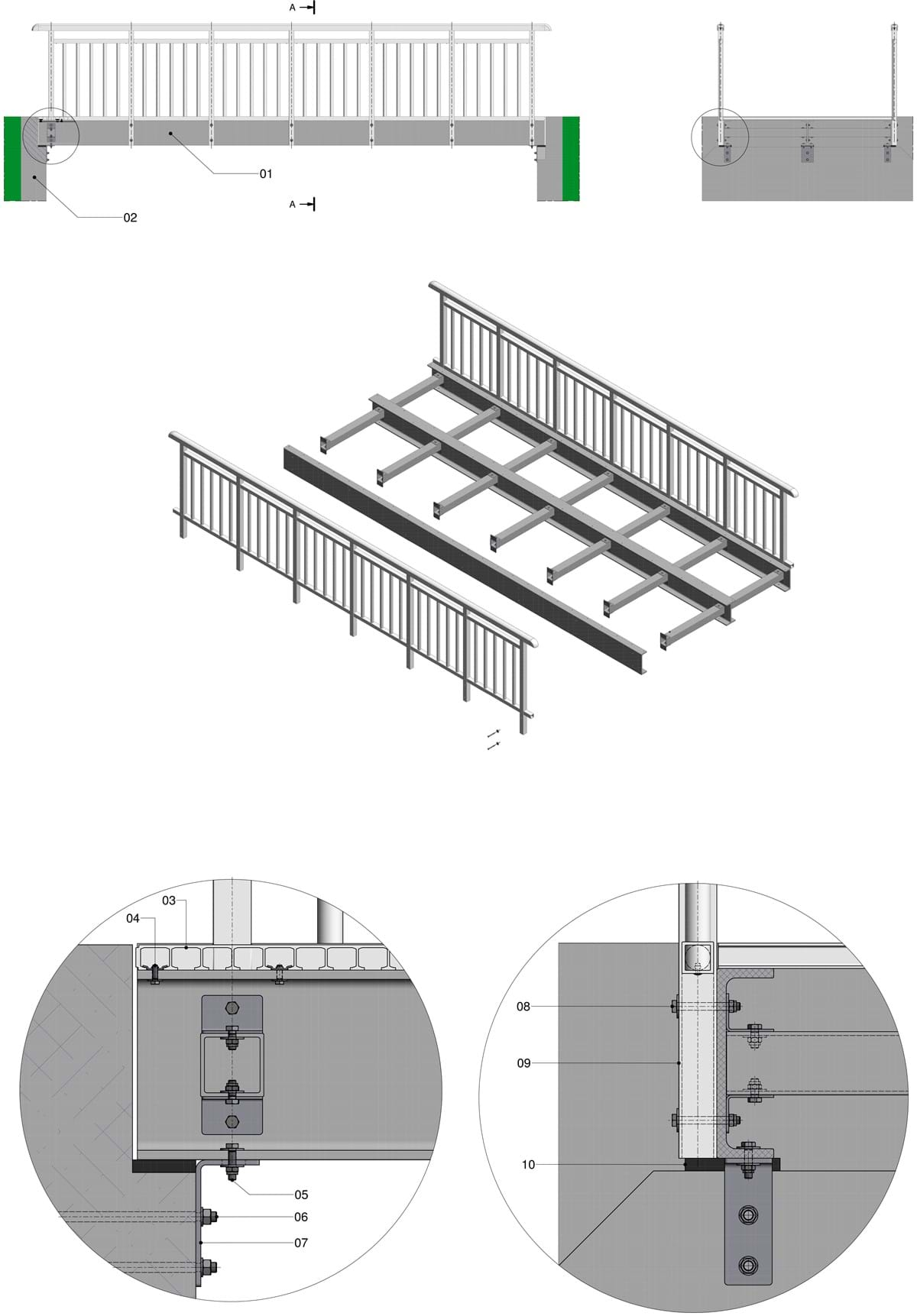

Illustration

The Fiberline Full FRP bridge uses material only manufactured by Fiberline Building Profiles A/S. The main girders are from large U- and I- profiles and the decking is made from HD plank. The railing is our standard bridge railing, also made fully from FRP.

1. Main girders, corners made from U-profiles, centre beams from I-profiles

2. Concrete foundations

3. HD plank, item no 122088

4. HD Clip, item no 149100

5. Bolts for attaching main girders to the foundation

6. Anchor bolt

7. Steel angle for attaching the bridge to the foundation

8. Bolte for mounting parapets to the U-profiles

9. Parapets made from square hollow sections

10. Neoprene pads for dampening and protecting the main girders

Data sheet for decking

Fiberline Medium Duty Plank

Fiberline Medium Duty Plank is designed with an excellent price-performance ratio. The plank weighs only 6.58 kg/m, making it easy to handle on-site. Like other products from Fiberline, plank MD is made of GFRP. This material has noteworthy properties such as a long, proven service life as well as high corrosion resistance and strength. Fiberline plank MD is also available with anti-skid surface

Fiberline Heavy Duty Plank

The strong Fiberline Heavy Duty Plank is suitable for applications were load requirements are 5 kN/m2 and point loads are 10 kN, e.g. decks for bike paths and pedestrian bridges. Plank HD is corrosion-free and has a long service life, even under demanding and corrosive conditions, e.g. swimming pools, industry and cooling towers settings as well as offshore. Other advantages include great strength, low weight and electrical insulation. Plank HD is also available with anti-skid surface.

Fiberline Ultra Duty Plank

The Ultra Duty Plank is our strongest bridge decking, designed to meet the most stringent load requirements for pedestrian and cycle bridges. The UD plank reduces the weight of the structure and is easy to work with at the installation site. It is also corrosion-resistant against a range of chemicals and salt water. Asphalt or PPMA/Epoxy strewn with sand or gravel can be used as a wearing surface.

It doesn’t have to take a long time to get a non-binding quote for a fibreglass bridge.

Fill out our form – it only takes you 2 minutes.

Our products are CE certified according to the EN13706 1-3 standard. This certification is your guarantee of consistently high quality every time you buy from us and use our products. Read more

Fiberglass enables lightweight and robust constructions, making installation faster. Although the material is comparable to steel, the specific weight of Fiberglass is only a quarter of steel. Read more

Fiberglass is an exceptionally strong material, rivaling steel, aluminum, and wood. Composite profiles offer similar weight to aluminum, while being just 20% the weight of concrete and 40% of steel, making them highly efficient. Read more

Composite materials are generally very durable, with only a few exceptions. They resist a variety of aggressive liquids and environments, resulting in long lifespan and minimal need for maintenance. Read more

Fiberglass is UV-resistant and can withstand temperatures between -40 and +80 degrees Celsius without deterioration of its properties. Additionally, it tolerates seawater and other atmospheric influences. Read more

Fiberglass profiles are electrically insulating. They are suitable for use in connection with all electrical constructions, such as along railway tracks, power plant installations, etc., as they are suitable for both low and medium voltage. Read more

The processing of fiberglass profiles is significantly easier than for metals such as steel, and just as efficient as for wood. This makes it easy to handle solutions with our profiles on site. Read more

Fiberline's fiberglass profiles have a significantly higher thermal insulating capacity compared to steel and aluminum. Read more

Fiberline's products are manufactured energy-efficiently through pultrusion. The low weight relative to strength and long lifespan make them a cost- and energy-efficient alternative. Read more