Working near or around railways tracks is difficult and costly affair since in many instances it will be necessary to interrupt the traffic. Being able to pre-assemble the GFRP stairways in advance is a distinct advantage, added to the fact that no earthing is required. GFRP is electrically non-conductive and therefore does not need to be earthed to comply with the safety regulations of many rail track authorities. Furthermore, the GFRP stair treads provide a non-slip walking surface, ensuring safe access. With lightweight GFRP the expected weight is around 20-30 kg/m for standard systems.

Illustrations

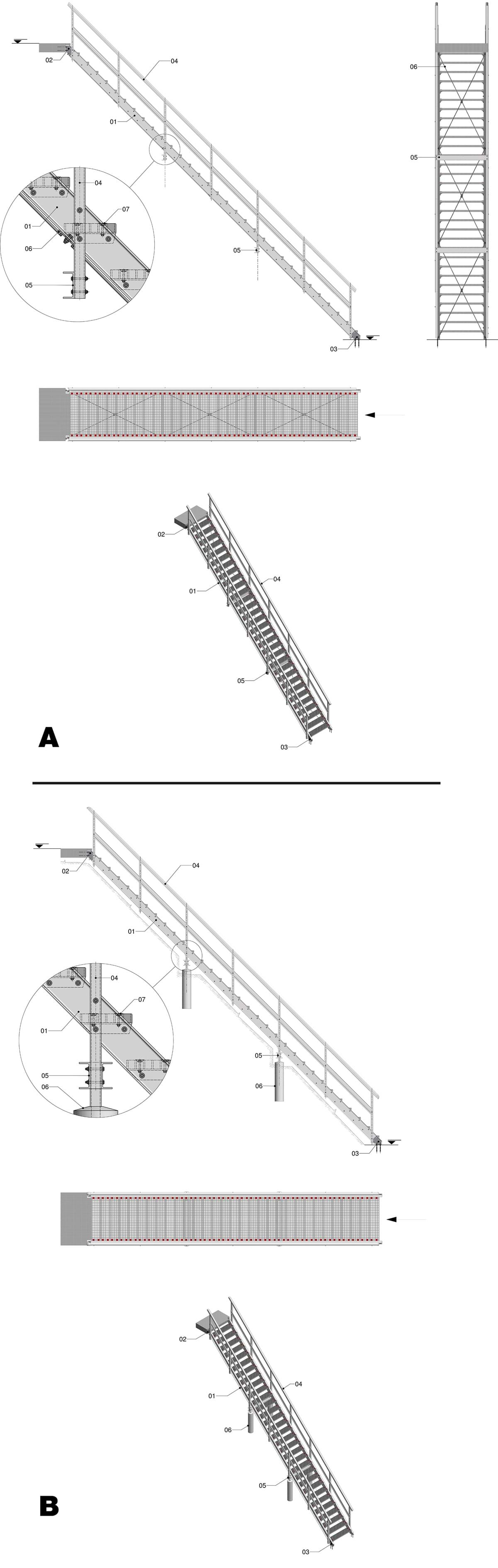

Shown below is a free-standing and supported stair system with bracing.

A: Evacuation stairs, free span

1. U-Profile stringer

2. Steel bracket for attachment to the platform

3. Steel bracket for attachment for the floor

4. Handrail profile, item no 122007

5. U-profile

6. Bracing construction

7. W Clip, item no 149108

B: Evacuation stairs, supported

1. U-Profile stringer

2. Steel bracket for attachment to the platform

3. Steel bracket for attachment for the floor

4. Handrail profile, item no 122007

5. U-profile

6. Concrete foundations

7. W Clip, item no 149108

Our products are CE certified according to the EN13706 1-3 standard. This certification is your guarantee of consistently high quality every time you buy from us and use our products. Read more

Fiberglass enables lightweight and robust constructions, making installation faster. Although the material is comparable to steel, the specific weight of Fiberglass is only a quarter of steel. Read more

Fiberglass is an exceptionally strong material, rivaling steel, aluminum, and wood. Composite profiles offer similar weight to aluminum, while being just 20% the weight of concrete and 40% of steel, making them highly efficient. Read more

Composite materials are generally very durable, with only a few exceptions. They resist a variety of aggressive liquids and environments, resulting in long lifespan and minimal need for maintenance. Read more

Fiberglass is UV-resistant and can withstand temperatures between -40 and +80 degrees Celsius without deterioration of its properties. Additionally, it tolerates seawater and other atmospheric influences. Read more

Fiberglass profiles are electrically insulating. They are suitable for use in connection with all electrical constructions, such as along railway tracks, power plant installations, etc., as they are suitable for both low and medium voltage. Read more

The processing of fiberglass profiles is significantly easier than for metals such as steel, and just as efficient as for wood. This makes it easy to handle solutions with our profiles on site. Read more

Fiberline's fiberglass profiles have a significantly higher thermal insulating capacity compared to steel and aluminum. Read more

Fiberline's products are manufactured energy-efficiently through pultrusion. The low weight relative to strength and long lifespan make them a cost- and energy-efficient alternative. Read more