Full FRP bridge 6 x 2 m

The bridge consists entirely of fiberglass profiles and combines several advantages such as low weight, corrosion resistance and minimal maintenance. This make GFRP bridges a sustainable, future-proof and cost-efficient solution.

Our fibreglass bridge is our pre-packed and unpainted bridge made exclusively of our fibreglass profiles and planks. When you buy our flat-pack solution, you assemble the bridge yourself, which is also the most budget-friendly solution. Click on "video" below and see how easy it is to assemble the bridge.

We offer the bridge pre-assembled both with and without painting. See all our variants below.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Items in stock: 10

4 weeks.

Not a member yet?

See personal prices, cut to size & view order history.

Need samples?

Why not buy a sample box before making up your mind?

Description

Description

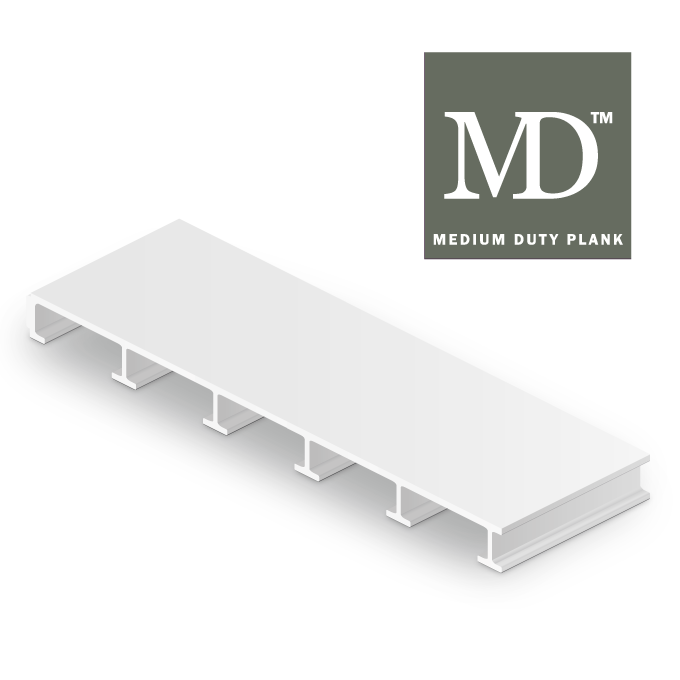

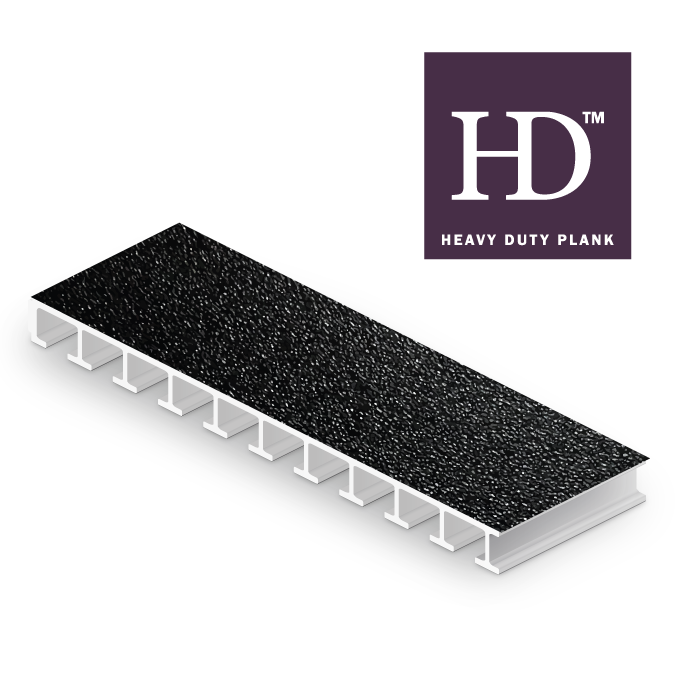

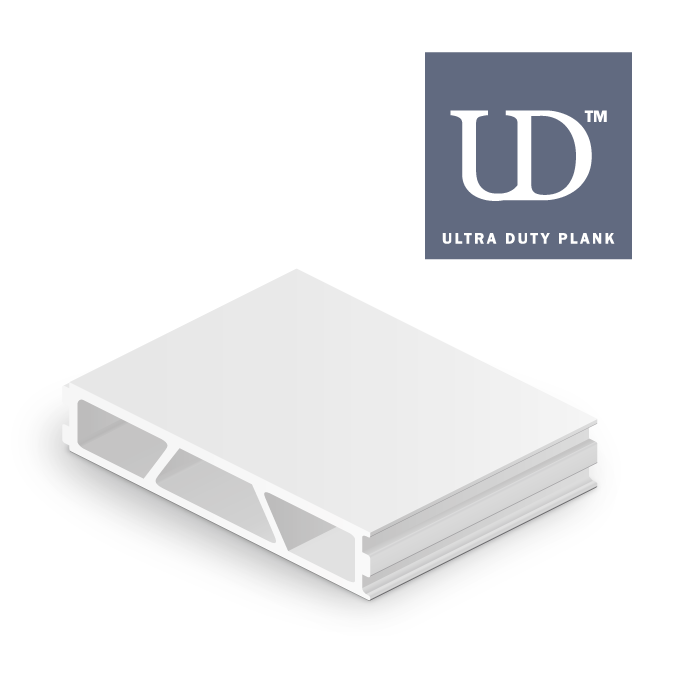

What typifies FRP bridges is that the substructure consisting of the bridge deck and the railings are all made of FRP profiles. Steel is used only in the form of bolts, nuts and washers. With the standard profile program from Fiberline it is possible to configure and build full FRP bridges up to a span of 20 meters.

Application

Full FRP bridges are usually pedestrian or bicycle bridges with traffic loads up to 12 tons. Spans up to 10 meters are possible with a girder-substructure while spans over 10 meters require trusses. Weight of the bridges is around 60-80 kg/m2 including the anti-skid surface and price is 1200-2000 EUR/m2*.

Quality and standards

Our profiles are certified according to a number of recognised standards, including CE, aBG and EN13706. This is your guarantee that you get a high, consistent quality every time you shop with us.

Quality and standards

Quality and standards

EN 13706-3:2002

ISO 9001

Video

Video

Downloads

Downloads